–

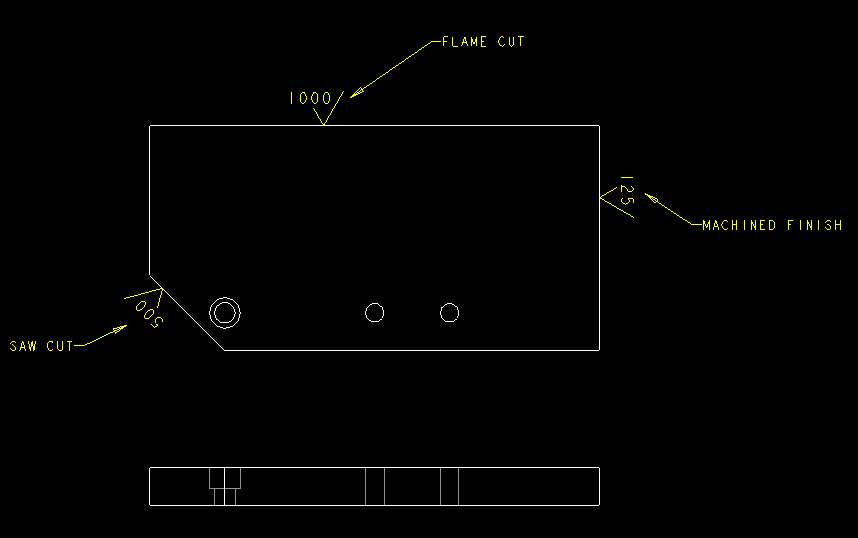

At Rentapen, we usually don’t use all the finish marks that are available. In Weld Fixture Design we will most likely use the following finishes. They serve the needs of most of our fixtures and their uses.

A 1000 is a flame cut.

A 500 is a saw cut.

Both of these are rough surfaces. Nothing is mounted to those surfaces or sets against those surfaces. It doesn’t need to be parallel or perpendicular to anything.

A 125 is for a mounting surface or even a surface that has some gliding on it such as the surface of a locating pin.

That’s it! Pretty simple, hey?

Machined Surfaces (125)

Make sure you include material for the machining.

Now, let’s say the shop is cutting off a 2″ square bar to be finished on one end. When it is machined it will be 3″ long.

So one end is saw cut (no machining) and the other end is machined. How long a bar does he/she cut?

The detail drawing should tell her/him. In the data section of the drawing title block, or in a separate data block, will be listed the size of the bar before it is finished.

2 x 2 x 3.125

The extra 1/8 inch is for machining off.

In the actual drawing you have the dimensions after it is machined.

Using CAD to make your parts, create a 2 x 2 x 3.125 block. Then cut one end off .125″.

When you are working with much bigger parts, you need to allow for .25″ of material for machining.

TIP

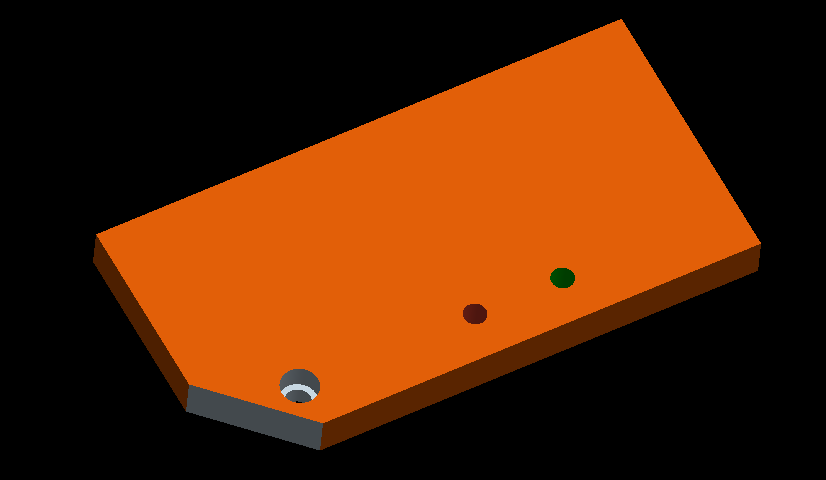

A nice trick to show that you have done your job in creating those finish cuts is to color all the surfaces of the block a different color than the block. Then when you create the finished cut it shows as a different color on the block. It makes it easier for the checker to check your CAD models.

The image above shows the cut surface and the machined c’bore easily.

At Rentapen we also color press-fit dowel holes red and slip-fit dowel holes green. So the engineer and the checker can easily see that there is not press-fit holes matching up with press-fit holes. There should always be a slip-fit matching up with a press-fit.

!!!NEWS!!!

We are very pleased to announce that Bill Kubricky has joined Rentapen as Project Leader for the Weld and Assembly Fixture Design and Build Projects. He has a history of helping manufacturers grow and managing manufacturing enterprises. We are glad to have him join us.

We’ve Gone 3 Wheelin’!

There are Excuses and there are Results. You can’t have both.

George, Rentapen’s Founder, and I, the Queen of Lean Machine Design are riding our recumbent tricycles to Florida from Northern Illinois. We rode our trikes around Wisconsin in 2008 and had a blast! So we were dreaming of doing it again. Rentapen has a great and dedicated team in place. There is no time like now to make it happen.

Next year, next month things can change, so we are going for it. We are heading out August 16th. If you would like to receive email updates about the journey, please email straley at rentapen dot com and put in the subject, “gone3wheelin”. And I will put you on the email list.

’til next time…

The Queen